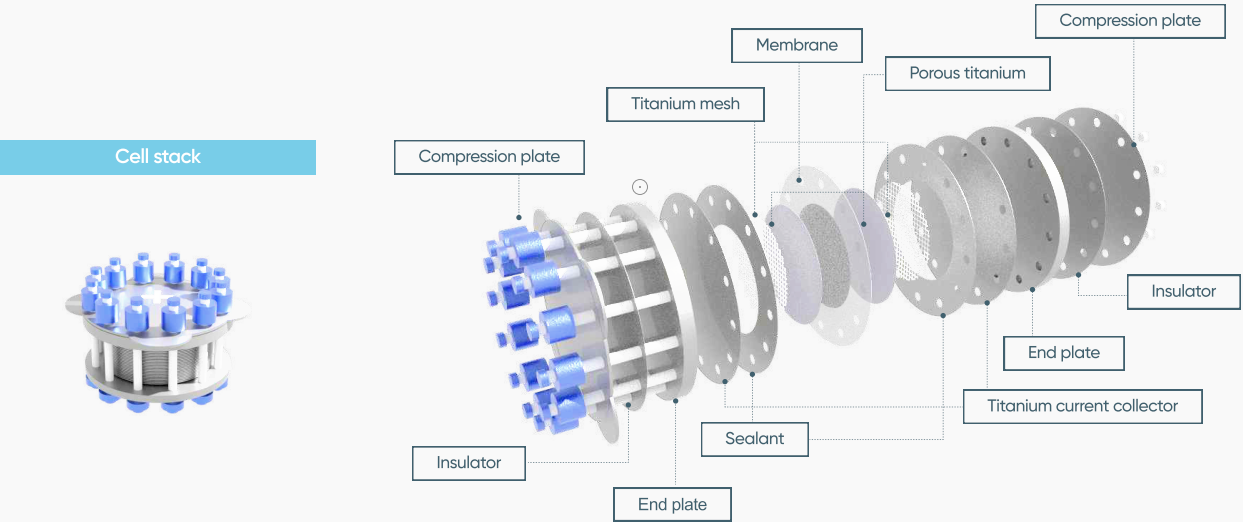

PEM (PROTON–EXCHANGE MEMBRANE TECHNOLOGY) FEATURES AND ADVANTAGES

Instead of an aggressive alkali solution, a solid polymer membrane with proton conductivity is used as an electrolyte

PEM VS ALKALINE ELECTROLYZERS

PEM - ELECTROLYZERS

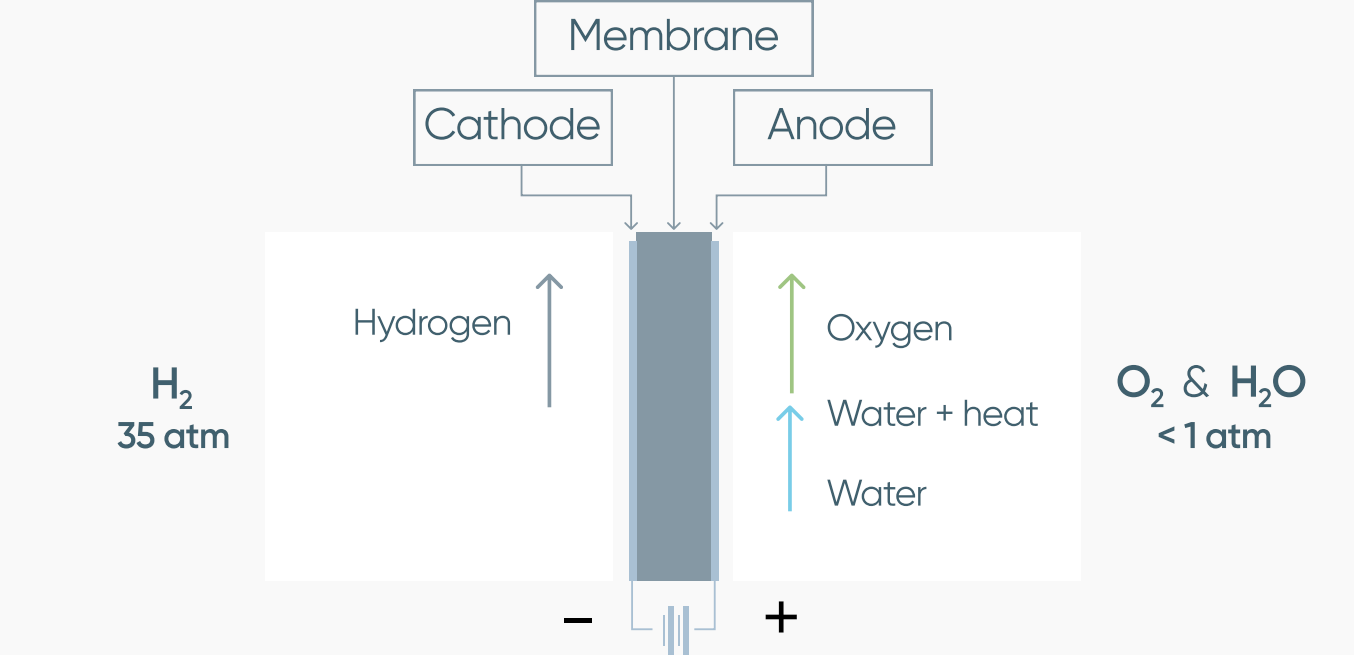

NOT AGRESSIVE, EASY, SAFE

- The only liquid is water

- NO corrosion

- The system works perfectly for many years

- Very easy to maintain

- The only impurity is water vapour (ppm)

- Impossibility of oxygen entering hydrogen

- Membrane is gas-tight — no hydrogen in oxygen

- Low pressure oxygen — no risks associated with pressurised oxygen

- Quick start and stop at any time

- Operation at 0-100% capacity automatically

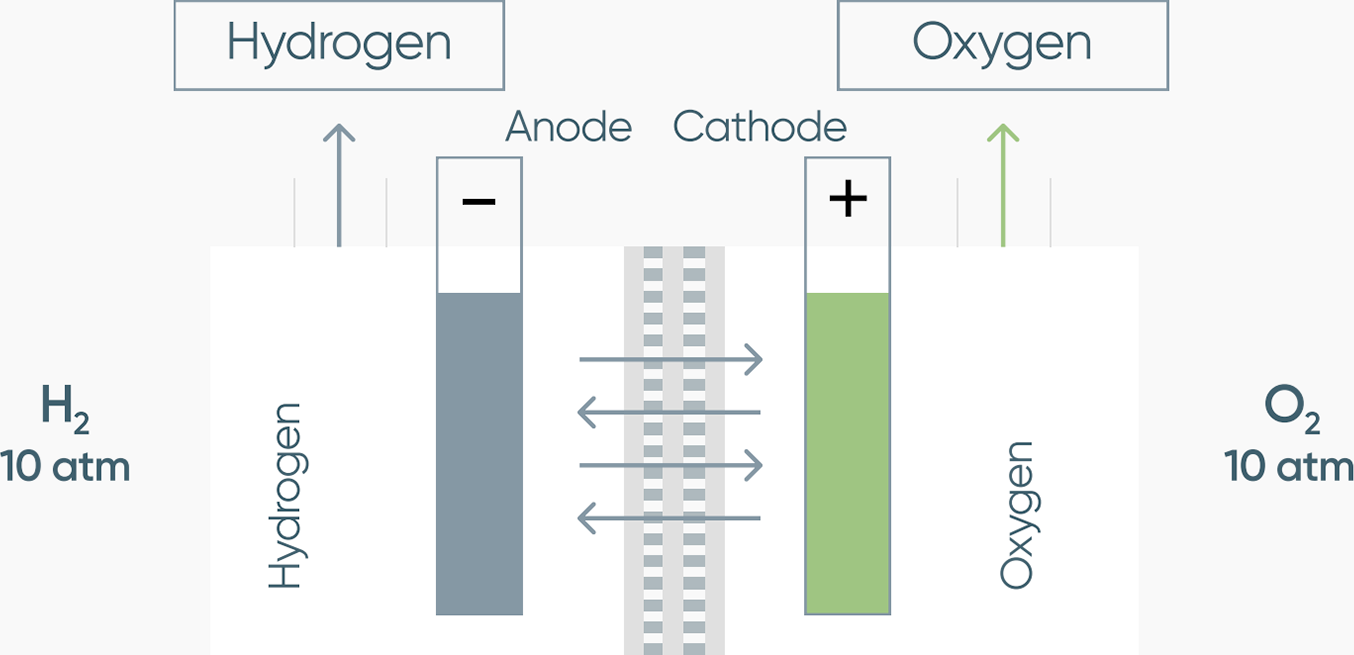

ALKALINE ELECTROLYZERS

AGRESSIVE, DIFFICULT TO REPAIR, NEED FOR OXYGEN MONITORING

- Filled with KOH alkali and operates at 80 C

- High corrosion + pressure LEADS TO risk of failure

- Loss of alkali — needs to be refilled

- Difficult to maintain (system draining)

- Repairs becomes more expensive every year

- Hydrogen contains alkali impurities

- Special clothing and facilities

- Continuous pressure balance

- High hydrogen content in oxygen

- High oxygen content in hydrogen

- Need to monitor pressure balance

- Oxygen at 10 atm next to hydrogen at 10 atm is a risk Nitrogen purging

- Difficult shutdown procedureShutdowns reduce service life